Aluminum and his alloys.

Aluminum and his alloys.

Aluminum is one of the most widespread elements in the earth’s crust. It is present in the form of silicates and oxides and constitutes about eight percent by weight. In pure form it is silver-white in color. It is very light, about 2.7 kg per cubic decimeter, and melts at about 660 ° C. It has excellent electrical conductivity, lower than that of copper in an absolute sense, but higher when compared to weight.

Exposed to air, it oxidizes quickly, forming a very compact and very thin film. This protects it from subsequent atmospheric attacks. The aluminum metal is mainly obtained from a mineral called bauxite. In the form of alum it was already known in antiquity. However, it only found great application at the beginning of the last century. This is thanks to the diffusion in the form of alloys.

Aluminum alloys.

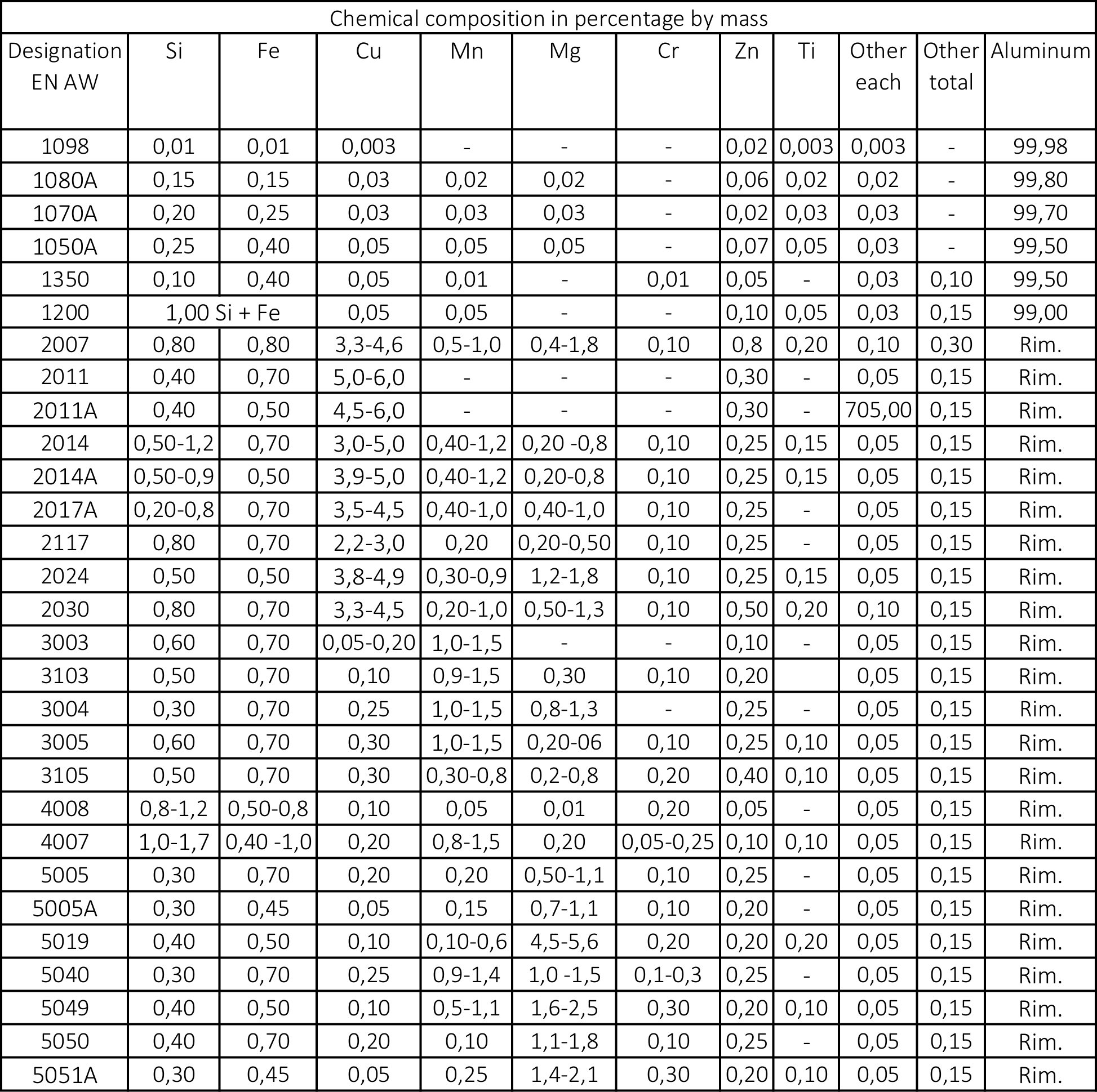

In order to improve the characteristics of the pure material, many aluminum alloys have been created. Basically, the peculiarities of the pure material are lightness, resistance to corrosion and electrical conductivity. However, to emphasize other particular characteristics, percentages of other elements are added. The main elements that are added are: copper, zinc, magnesium, silicon, chromium, iron, titanium, tin, nickel. Thus, for example, alloys with high mechanical resistance, alloys that are very ductile and workable or with excellent castability characteristics are obtained. Or alloys with increased corrosion resistance, more resistant to traction or high hardness.

Classification

Aluminum alloys can be classified according to various criteria. The national unification body UNI divides them into two groups. Group G, for foundry, and group P, for plastic processing. These are then further sub-classified according to the metal most present in percentage after obviously aluminum. For example aluminum-magnesium or aluminum-zinc alloys. Alloys are often commonly referred to by trade names, sometimes deposited, such as anticorodal, ergal, avional, etc. Classifying on the other hand based on use, we have alloys for general uses, corrosion resistant alloys, for pieces that operate above 100 ° C or for special uses.