Online metal laser cutting

ONLINE metal laser cutting – FREE QUICK QUOTES Metals

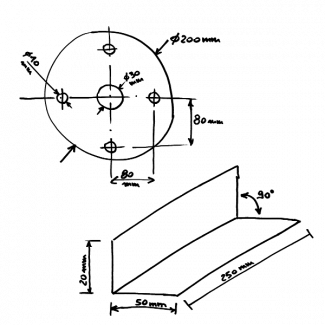

EVEN WITHOUT CAD DRAWINGS

ASK FOR A PRICE ONLINE

ALLUMINIUM ● CORTEN ● STAINLESS STEEL ● IRON

DESCRIBE THE PIECES OR SEND SKETCHES

Fill out the FREE quotation request form by entering:

SEND IMAGES TO CUT

Fill out the FREE quotation request form by entering:

- Material

- Thickness

- Your email on which to receive the quotation

- Enter quantities in the text space.

- Send us one or more images with the shapes you want to make in metal in PDF, JPG or PNG format.

UPLOAD CAD FILES

Fill out the FREE quotation request form by entering:

- Material

- Thickness

- Your email on which to receive the quotation

- Enter quantities in the text space.

- Send us one or more CAD drawings images in the format you prefer.

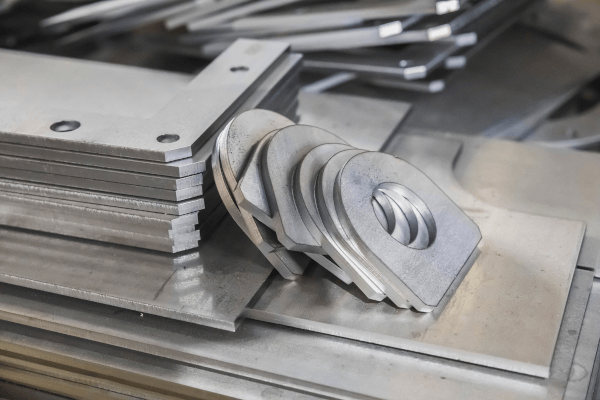

CUSTOM ONLINE SHEET LASER CUTTING SERVICE

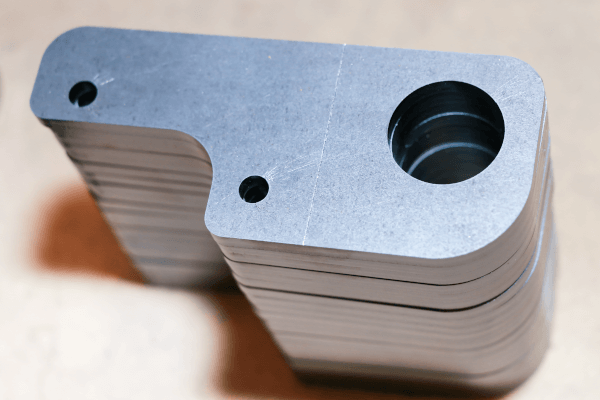

Cutstom is an online service for the sale of customized pieces in metal sheets made using laser cutting technology and bent with CNC technology.

First of all, it aims to meet the needs of those who are not particularly familiar with metal laser cutting technology and at the same time do not have the ability or the skills to create a CAD drawing in digital format. In particular it refers to individuals and professionals such as designers and planners who need small series or prototypes.

The Cutstom CNC laser cutting and bending service works in synergy with the potential customer, helping them to pursue the goal of obtaining their pieces directly at home even without special skills in metal processing.

Estimates are always clear and quick and the start of processing is subject to the approval of the processing draft.

Metal sheet laser cutting online

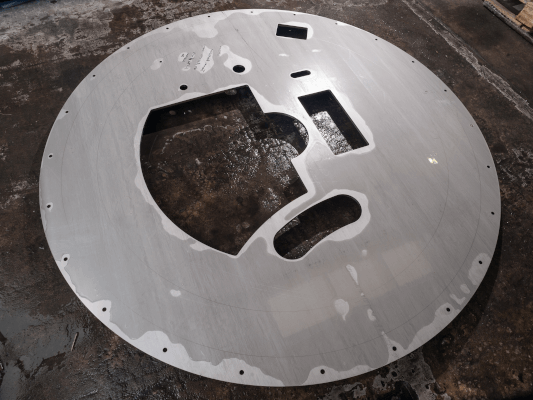

Come funziona la lavorazione di taglio laser della lamiera? Il taglio laser lamiera è una lavorazione che consente di ottenere particolari metallici tagliati a disegno per svariati settori merceologici ed industriali. Per fare le diverse lavorazioni di taglio si utilizzano macchinari laser in fibra ottica con piani di lavoro da 3000mm x 1500mm. Questi macchinari che utilizziamo per effettuare lavorazioni di taglio laser lamiera ci consentono di tagliare metalli con spessori fino a 15 mm ed effettuare taglio laser su lamiere di ferro, acciaio inox, alluminio, lamiera zincata, rame, ottone e titanio.

Dato che i macchinari per il taglio laser lamiera fanno parte del programma di investimento Industria 4.0, essi consentono quindi di controllare in tempo reale lo stato delle lavorazioni taglio laser, con appositi programmi gestionali dedicati, oltre che ottenere assistenza immediata da parte del produttore per eventuali guasti o ottimizzazioni dei processi produttivi.

Grazie alla sua flessibilità, il macchinario in questione è ottimale per processi di prototipazione in tempi rapidi, con la massima affidabilità e precisione.

CNC bending following online sheet metal laser cutting

Why do we perform the bending operation? CNC bending processes are usually a natural next step of sheet metal laser cutting. After laser cutting, in fact, we are often asked to carry out various types of bending on the shaped pieces. Generally, the bends are also specified by the customer through construction drawings, but we can also help the customer by taking over the drawing operation.

What types of pieces can we fold? Our press brakes have a power of 100 tons and useful work surfaces of 3000mm, they are also able to carry out processing of:

CNC bending machines are extremely versatile in fact they allow us to work pieces of small and large dimensions. This always with a view to optimizing costs and personalizing customer requests.

How did the opportunity arise to provide a bending support for metal pieces? The CNC bending machines are also part of the Industry 4.0 investment program and therefore allow you to check in real time, as well as for laser sheet metal cutting, the status of CNC bending processes with specific dedicated management programs. Thanks to these devices, in fact, we can obtain immediate assistance from the manufacturer for any failures or optimizations of production processes.

Furthermore, the flexibility of the sheet metal bending machinery is optimal for rapid prototyping processes with maximum reliability and precision.

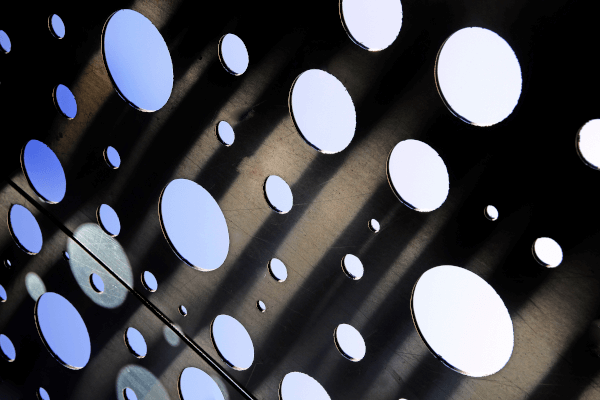

MATERIALS FOR laser cutting sheet metal online

Only high quality raw materials with a certificate of origin are used. The customer can choose from a variety of sheets with a wide range of strength, conductivity, weight and corrosion resistance.

Pieces are made in Aluminum, Steel, INOX and CORTEN using CO2 and Nitrogen laser cutting machines that allow high precision cuts and engravings. Furthermore, both prototypes and series of pieces can be ordered.

The thicknesses treated vary from 0.5 mm to 10 mm and the maximum size of the format is 1500 mm x 3000 mm.

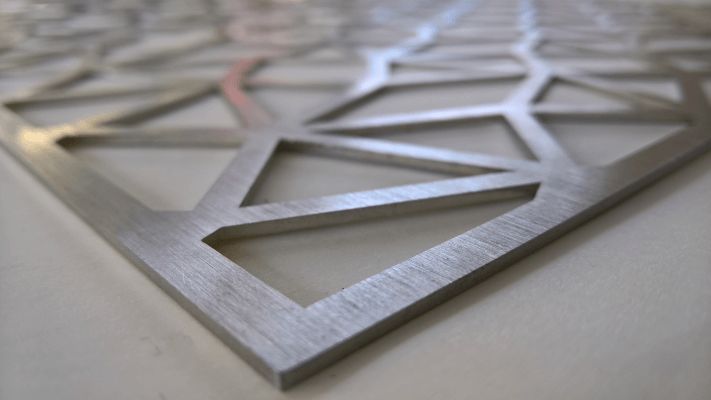

PRECISION OF LASER CUTTING and CNC bending

A standard tolerance level for most CNC laser cuts ranges from 0.1 to 0.2mm. But tolerance levels can be tailored to customer needs.

The accuracy offered is in accordance with the tolerance tables ISO 2769 (Standard, Fine) and ISO 286 (Degrees 8,7,6).

The advantages of laser cutting are speed and accuracy. Using the most advanced laser cuts, we produce extremely accurate and rapid components in just a few working days.

We guarantee the quality of the supplies by carrying out a check after laser cutting and bending and this on both samples and series of pieces.