Characteristics 1050 Aluminium Alloy

Characteristics 1050 Aluminium Alloy – PRICES Online Laser Cut

characteristics 1050 aluminium alloy.

In this short page you will find some useful information on the technical, physical and chemical characteristics of this formidable metal alloy.

DESCRIPTION

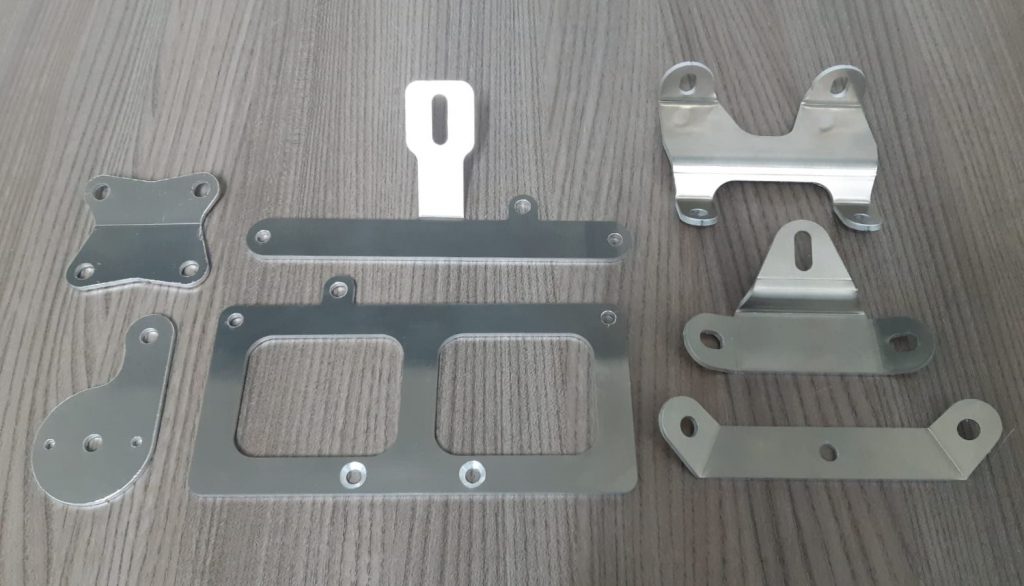

It presents an excellent compromise between the aesthetic aspect, the plastic deformability and the mechanical resistance. It is suitable for extrusion, drawing and lamination. It also has excellent corrosion resistance. It is usually available in the annealed condition H18 and H24.

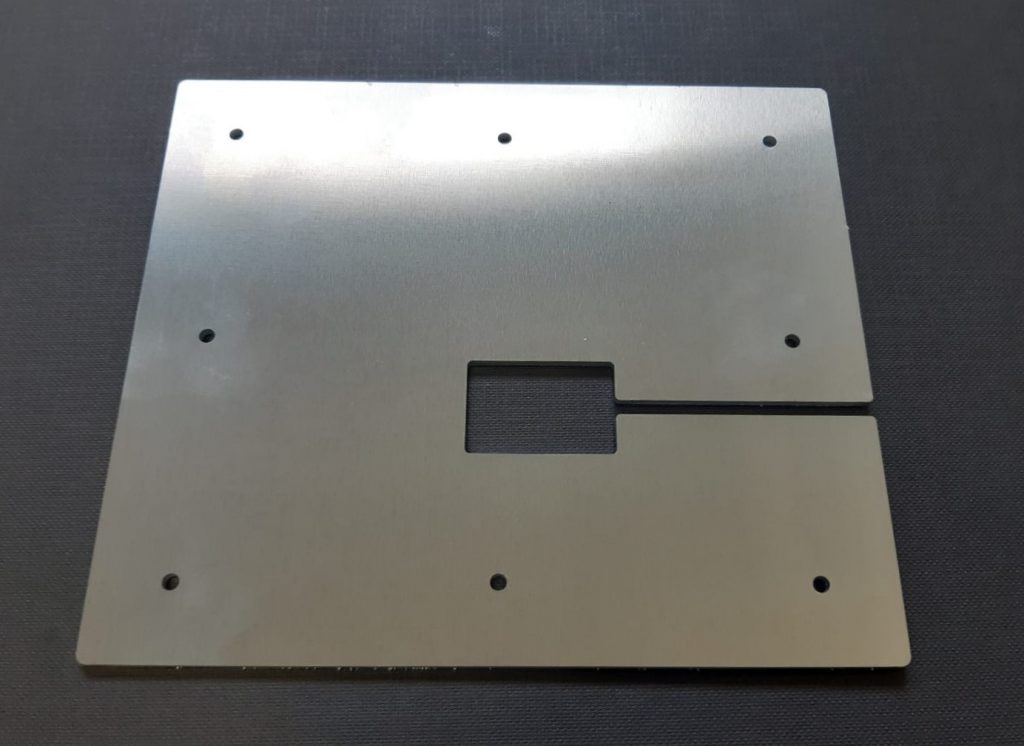

Cutstom is a specialized center for laser cutting and sheet metal bending, has a great experience in the processing of aluminum alloys and always ensures excellent results.

Application of use.

3000 mm x 1500 mm

2000 mm x 1000 mm

Available thicknesses

PHYSICAL CHARACTERISTICS

Aluminum 1050A

Density – 2.70 g / cm ^ 3 at 20 ° C

Modulus of Elasticity – 10,000 N / mm ^ 2

Melting temperature – 650 – 658 ° C

Thermal conductivity – 209 W / m ° C at 20 ° C

Flexural strength due to fatigue – 3/5 kg / mm ^ 2 – Status H24

Coefficient of thermal expansion – 25

Hardness:

– 18 HB – State 0

– 38 HB – State H18

– 26 HB – H24 status

Fair machinability on machine tools.

Good TIG and MIG weldability.

Good aptitude for anodizing.

Medium corrosion resistance.

MECHANICAL PROPERTIES

Aluminum 1050A.

Yield Strength:

– minimum Rm 70 Mmm ^ 2 for State 0

– minimum Rm 160 Mmm ^ 2 for State H18

– minimum Rm 100 Mmm ^ 2 for State H24

– minimum Rm 115 Mmm ^ 2 for State H26

Tensile strength:

– minimum Rp0.2 = 20 Nmm ^ 2 for State 0

– minimum Rp0.2 = 130 Nmm ^ 2 for State H18

– minimum Rp0.2 = 70 Nmm ^ 2 for State H24

– minimum Rp0.2 = 85 Nmm ^ 2 for State H26

Brinnel hardness:

– minimum 18 HB for State 0

– minimum 38 HB for State H18

– minimum 26 HB per State H24

– minimum 31 HB for State H26

Percentage elongation:

– minimum 30% for State 0

– minimum 4% for State H18

– minimum 7% for 24 hours a day

– minimum 6% for State H26

Equivalences

Europe – EN 573 – En AW 1050A Al 99,5

FRANCE – AFNOR – 1050A

GERMANY – DIN – Al99,5

GREAT BRITAIN – BS – 1050A

U.S.A. – ASTM – 1050A

characteristics 1050 aluminium alloy

THE INFORMATION ON THESE PAGES HAS BEEN DRAFTED WITH CARE BUT CONTAINS ONLY INDICATIVE AND NOT BINDING DATA.

THERE MAY BE ERRORS FOR WHICH WE DO NOT ASSUME ANY LIABILITY.