Drawing for laser cutting: On this short page you will find useful tips for designing your pieces.

Drawing file exchange formats.

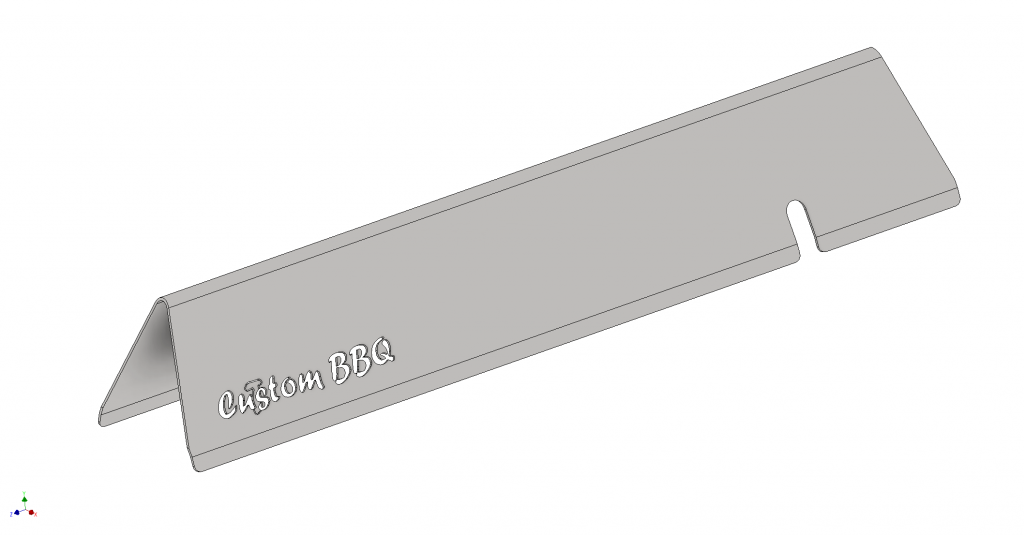

The designs you can produce are generally either two-dimensional (2D) or three-dimensional (3D) models.

Whatever drawing program you use, it is important to avoid compatibility problems with those who will perform the laser cutting process for you. For this you should export the 2D drawings in the neutral DXF or DWG exchange formats and the 3D models in the neutral IGES (.igs) or STEP (.stp) formats.

Features of designs for laser cutting.

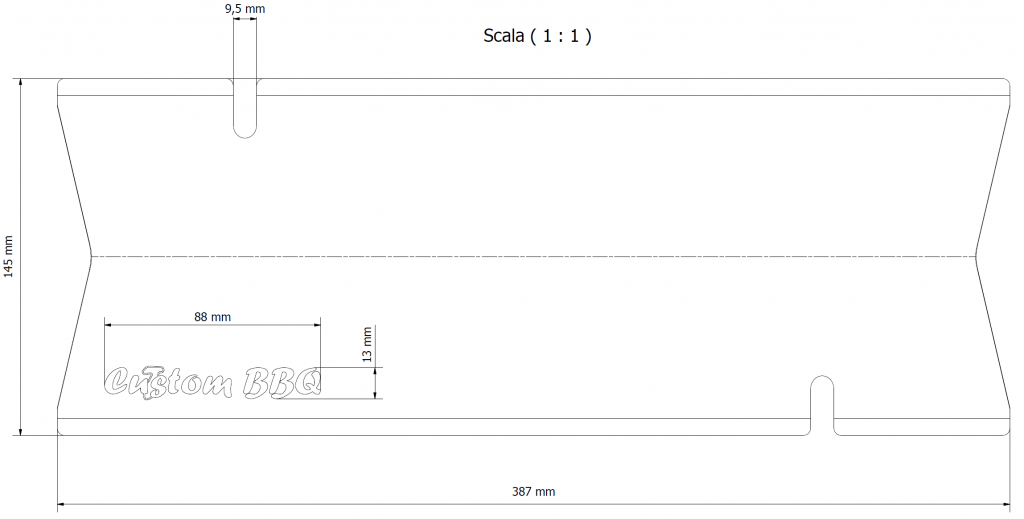

If you send a 3D model, remember that in order to be laser cut, your piece will still have to be traced back to a two-dimensional path. For this you have to pay close attention to setting the right thickness for your piece. It is also important to give some information on the maximum dimensions of the object. This is to avoid problems of understanding on the scale of the piece.

As far as two-dimensional drawings are concerned, make sure that the internal or external contours of your pieces are always formed by closed lines. If the geometries are open, the person who will cut the piece will almost always have to arrange the design to close the contours. And every time you intervene you can obviously introduce errors. Also in this case do not be satisfied with sending the geometries and the writing of the staircase but put a couple of significant control dimensions.

How to economize by drawing.

The standard formats of the metal sheets are usually 1000×2000, 1250×2500 and 1500×3000.

For this reason, if you draw large pieces, you must check that they do not exceed these dimensions and try to fit as much as possible within the sheet. If you are unable to insert other small pieces to fill the gaps between the large pieces you will also be charged for the cost of the waste material. Your piece will therefore be less economical.

Useful tricks to increase the quality of the cut.

Always try to put small radii in each sharp corner if your project allows it. Sharp edges, especially acute ones, tend to burn with laser cutting.

Keep in mind that by increasing the thickness of the pieces, the accuracy of the measurements and the quality of the cut profile will deteriorate.

Also keep in mind what you want the beautiful side of your piece to be. Sheet metal sheets are very heavy, and in laser cutting machines they sit on pointed grids. The underside of the plates is almost always slightly scratched. Especially in softer materials such as aluminum. In addition, the contour of the cut is also increasingly beautiful on the upper face, where the laser beam enters the workpiece.